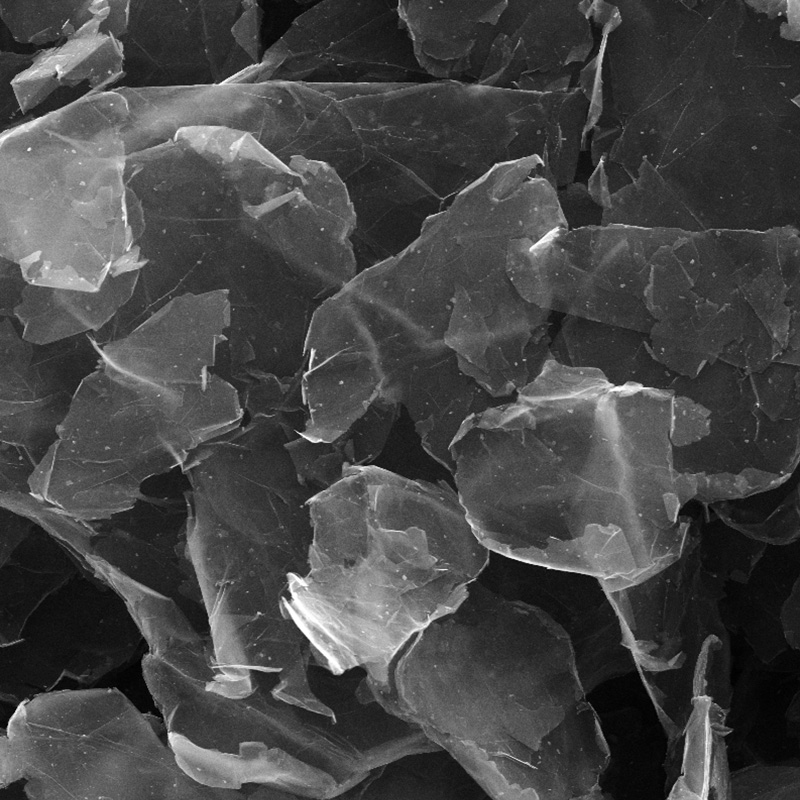

Utilising a proprietary high-efficiency water exfoliation technology involving graphite-based precursors, Nanesa produces various grades of graphene (GRM) used in the development of custom formulations and products for industrial clients.

The production facility, in combination with the GRM production system, features a G-Paper production line capable of producing a range of thicknesses and formulations, a department dedicated to coating formulations, and a department focused on the production of additives for the corrugated board industry.

NANESA operates three facilities dedicated to R&D and quality control for GRM and graphene-based semi-finished products.

Dedicated to the development of GRM materials and semi-finished paper products. It is a fully equipped chemical laboratory where quality control analyses of production processes are also integrated.

Our electrochemical lab is equipped for the development and testing of metal-graphene composites, with a focus on tribological, super lubricant, electrical and thermal properties.

Our company is equipped with a GRM-based formulation development laboratory that includes G-Paper prototyping capabilities, along with a comprehensive range of characterisation instruments. These include DSC, TGA, SEM, PSA and XRD analysis.

At Nanesa, we prioritise innovation, offering our clients cutting-edge solutions that incorporate graphene. Our team is dedicated to providing continuous support and expertise throughout the partnership, ensuring the delivery of materials that surpass expectations in terms of performance.

The company's R&D team conducts a feasibility study to assess the viability of meeting customers' innovation requirements, identifying risks and potential challenges in the development phases that follow.

The development work proposed to the customer is studied and planned in detail, taking advantage of the strong synergy between the various technical resources in the company. The solutions are developed taking into account the client's technological constraints, facilitating the integration of innovative GRM-based materials within its established technological processes without compromising continuity.

The R&D team at Nanesa is dedicated to problem solving and has the expertise to understand the customer's technological challenges, even proposing engineered solutions to complex innovation issues.

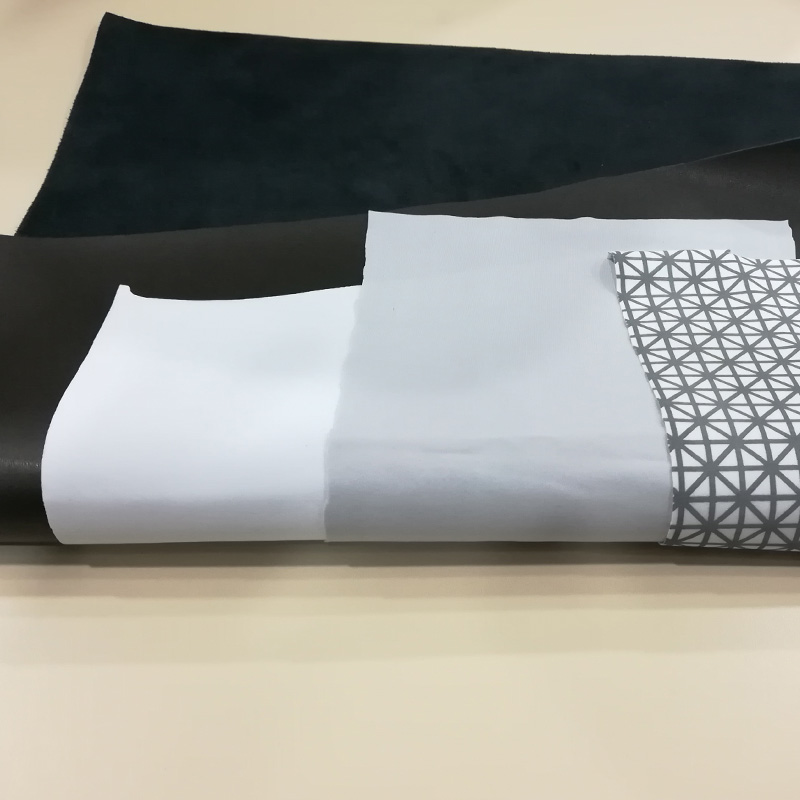

The synergy with the company Spac S.p.A. of Arzignano (leader in the production of synthetic leather and laminated technical materials), has led to the development of an innovative composite material based on PU-GRM, produced in rolls, capable of providing heating properties to substrates of different nature in the absence of metal resistances. This innovative thermoresistor exploits the properties of graphene to be flexible and highly efficient, reaching very high heating and cooling speeds and uniformity, with high versatility of use (it can be used in combination with multiple substrates fabrics, leathers, fake leathers) and robustness.

Nanesa supports Tetra Pak in research activities related to the development of advanced materials and the creation of prototypes that integrate some of the properties of graphene in high-performance devices for packaging applications.

The research and development activities are focused on the potential of graphene for thermal management applications.

The aim of this collaboration is to conduct research and development activities to integrate GRMs in elastomeric matrices.

This collaboration focuses on research activities related to the experimental procedures for the functionalisation of graphene in elastomers.

The research activities are centred on the utilisation of additive polymer composites with GRM for mechanical reinforcement. Furthermore, a collaboration has been established for the characterisation of graphene sheets using a comprehensive range of experimental techniques.

The aim of this project, which is being supported financially by the Tuscany Region as part of the SensoGM initiative, is to develop new synthesis techniques for silver nanostructures and silver-graphene hybrids. These innovative substrates are intended for use in SERS techniques.

The aim of the collaboration is to develop of GRM functionalisation techniques through a ball milling process.

The aim of the project is to explore the potential of functionalised GRMs in the context of electrodeposition processes for the production of metal-graphene coatings.

The project involves the characterisation of the corrosion resistance properties of metal-graphene composites for applications in electrical mechanisms (Circuit Breakers Project). The project also covers the prototyping of graphene sheets and the integration of CFRP techniques.

Characterisation of tribological and structural properties of metal-graphene composites for applications in electrical mechanisms (Circuit Breakers Project).

The project involves the development and realisation of a prototypes of sheets for the development of ice sensors for aeronautical applications (GICE project).

Our collaboration with University of Cassino is focused on materials with high thermal dissipation. We are developing predictive models for thermoelectric properties and creating prototypes using a 3D printing process with Ultem® and graphene-based coating for EMI shielding properties.

Nanesa provides support to ELESIA in the development of high-value-added solutions for thermal management and EMI shielding of composite materials (electronic applications in various industries).

At Nanes and Marigi, we are working together to develop high-performance coatings for the thermal improvement of components for racing applications. These include radiators, discs and brake calipers for motorsport.

Nanesa provides support to Punto Quantico in the development and production of graphene-based additives (designated as JB18 and JB18s) for the enhancement of gluing performance and production efficiency in the corrugated industry.

At Nanesa, we specialise in the development and production of low-thickness, high-performance graphene sheets for use as heat spreaders in biomedical applications, particularly in ultrasound probes. These innovative solutions are designed to enhance the performance of Esaote's products.

The partnership with ABB's Research Centre has resulted in the development of multilayer metal-graphene composites, produced by electroplating deposition processes. These composites are capable of providing electro-mechanical components with solid lubrication characteristics (lower coefficients of friction than standard solutions), resistance to abrasion even under high loads, and resistance to corrosion and oxidation.

The innovation extends to the manufacturing of mechanism components for medium-voltage electrical switches, as demonstrated by the submission of three European patents.

Nanesa‘s added value lies in its ability to offer customers innovative graphene-based solutions, developing materials with superior performance through continuous customer support during the partnership.